Dental Burs The three basic parts of a bur are the head, the neck and the shank.

Dental restorative burs are typically made from tungsten carbide or a diamond particle coating of varying degrees of roughness depending on the purpose of the bur, bonded to the underlying metal bur head. They can be used for caries removal. Surgical burs are fabricated from tungsten carbide.

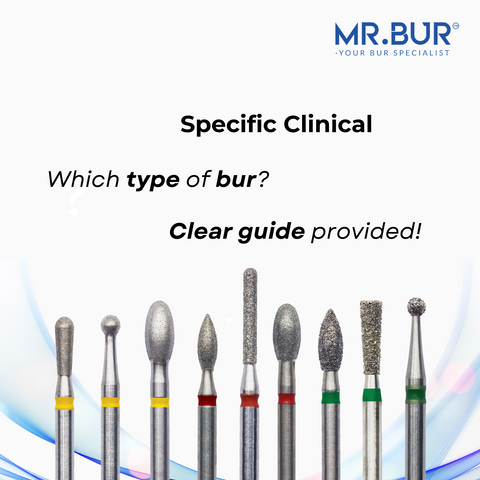

Operative and surgical burs

Tungsten carbide burs, the head contains blades that produce the cutting action. The cutting property of a bur varies with the positioning and the degree of angling of the blades. More obtuse angles will produce a negative rake angle, which increases the strength and longevity of the bur.

Acute angles will produce a positive rake angle, which offers a sharper blade for quicker cutting but which dulls sooner. Additional cuts across the blades, called “crosscuts,” can be added to increase cutting efficiency.

Dental burs are designed with different flute angles and cutting characteristics specific to the task for which they are designed.

Operative or cavity preparation burs

Operative or cavity preparation burs have flutes that are cut deeper and wider, creating a higher degree of aggressive enamel cutting with increased speed and efficiency. Typically, these operative burs are either straight bladed (plain) or crosscut. Straight-bladed burs cut smoothly but are slower, especially with harder materials; crosscut burs can cut faster due to the lack of debris build-up. In the case of diamond-coated burs, a smooth shape is created and a fine-, medium- or coarse-ground diamond coating is applied over it.

Mr Bur Carbide Burs

Mr Bur Carbide Burs for restorative procedures ranging from gross removal of tooth structure to removal of dental materials. resistant to cutting.

Removal of a fixed restoration

Cutting through porcelain is best accomplished using a diamond bur. A diamond-fissure bur maximizes the length of area removed at one time. Following this, metal is best removed using a tungsten carbide bur. Finally, the underlying preparation is refined using a tapered-fissure bur.

Removal of an existing amalgam

Efficient removal of amalgam is best accomplished with a tungsten carbide bur. Fast efficient removal of amalgam can be obtained using straight-fissure bur, as well as carbide pear shaped burs and fine crosscut burs.

Removal of caries

Caries present can be safely removed using a round tungsten carbide at slow speed. Using a round tungsten carbide at slow speed helps to remove the minimal amount of dental hard tissue while also removing the softer carious areas and, in the case of deeper cavities, reducing the risk of iatrogenic pulpal exposure. If desired, a caries detection solution can be used to ensure that the caries is thoroughly removed. Following caries removal, a finer smoother carbide or diamond can be used to complete the preparation, prior to restoring the tooth. The cases below demonstrate the use of this two stage approach using fissure burs followed by large round burs.

Finishing burs fabricated from tungsten carbide have more flutes closer together and shallower than do operative burs, for the fine finishing and polishing of dental materials. Either diamond or tungsten carbide finishing burs can be used to remove composite and to improve the smoothness of the restoration prior to polishing with cups/discs/liquid polish, which optimizes smoothness and thus reduces the potential for biofilm development on the composite’s surface.

MR. BUR Canada provides a wide range of dental burs globally.

Diamond Burs, Carbide Burs, Surgical & Lab Use Burs, Endodontic burs, IPR Kit, Crown Cutting Kit, Gingivectomy Kit, Root Planning Kit, Orthodontic Kit, Composite Polishers, High Speed Burs, Low Speed Burs

Subscribe our newsletter now!